JNX-clusives

Chips Off the Old Block

and other ruminations about masonry

by

by

Manufactured Stone Veneer

In my last installment, I promised to provide some installation details for the Adhered Manufactured Stone Veneer system. I have read many from a variety of different manufacturers, and I am going to summarize them for you here... with this caveat -- the Adhered Manufactured Stone Veneer (AMSV) industry is not currently recommending the use of a drainage plane in their installations. The final word on this has not yet been written, but I find it difficult to recommend the system without one. So the drawings I have provided here show one -- in this case, it is Sure Cavity by Masonry Technologies, Incorporated, which is a recycled plastic material with a built-in filter fabric that looks like this...There are other manufacturers that make drainage plane (and drainage mat) products, such as DC14 Drainage Mat manufactured by Greenguard, or fibrous entangled filament drainage mats. You can choose one that you like.

Adhered Manufactured Stone Veneer Installation Recommendations

(taken from the Masonry Veneer Manufacturers Association Installation Guide, 3rd Edition)

(These recommendations apply to wood framed exterior walls made with moisture sensitive- materials; the application is slightly different when applied to concrete or masonry walls, but I am not going to address those applications in this installment)According to the Masonry Veneer Manufacturers Association (MVMA), the weep screed should be installed so that the bottom of the AMSV system is at least 4" above the surrounding grade.

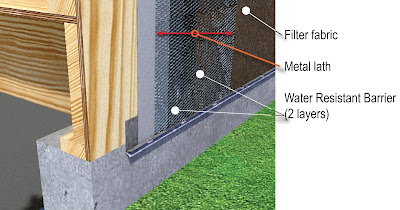

Then a 2-ply water resistant barrier should be installed. The plies should be installed in a shingle-lapped manner, overlapped by 2" (6" at the vertical joints).

|

| Figure 3-- Add 2 layers of Water Resistant Barrier |

Then the drainage plane or drainage mat, or rainscreen should be installed over the water resistant barrier...

|

| Figure 4-- Add rain screen drainage plane |

|

| Figure 5-- Enlarged view of rainscreen drainage plane |

|

| Figure 6-- Filter fabric comes already installed on rainscreen drainage plane |

The MTI drainage rainscreen is already covered with a filter fabric to keep the mortar scratch coat from filling the drainage cavities.

Then metal lath is installed. I have seen many installations on houses around where I live that have used chicken wire, but I have found no recommendations from any source that recommend that.

|

| Figure 7 |

Now the wall is ready for the mortar scratch coat, or setting bed. This is what holds the manufactured stone in place.

|

| Figure 8 |

Then the manufactured stone must be installed with great care and skill...

|

| Figure 9 |

Please give me a call if you would like to discuss this further. I'm always happy to talk with you about these kinds of things (or a little baseball, too).

Until next time...

NOTE: This document was prepared by the JNX Group, LLC and is disseminated for informational purposes only. Nothing contained herein is intended to revoke or change the requirements or specifications of the individual manufacturers or local, state and federal building officials that have jurisdiction in your area. Any question, or inquiry, as to the requirements or specifications of a manufacturer, should be directed to the manufacturer concerned. The user is responsible for for assuring compliance with all applicable laws and regulations.

The information provided here is provided for informational purposes only, and includes the opinions of the author. Nothing contained herein shall be interpreted as an endorsement of any particular product or manufacturer, or as a warranty by JNX Group, LLC, either express or implied, including but not limited to the implied warranties of merchantability, fitness for a particular purpose or non-infringement. In no event shall JNX Group, LLC be responsible for any damages whatsoever, including special, indirect, consequential or incidental damages or damages for loss of profits, revenue, use or data, whether claimed in contract, tort or otherwise.

Drawings copyright JNX Group, LLC. All rights reserved.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.